top of page

WHAT EXACTLY WAS V1 OF PROJECT PHOENIX?

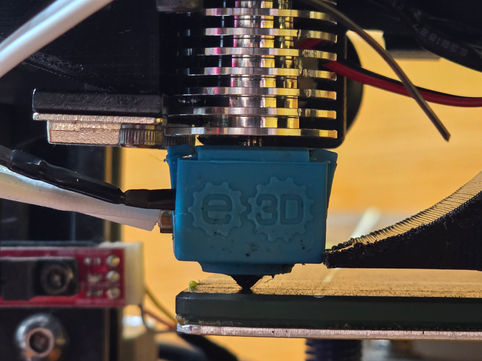

In the first iteration of Project Phoenix, I took an Anycubic Chiron, stripped it of all its locked electronics, and replaced them with standardized, open-source equipment. Specifically:

-

Replaced all generic motors with proper Nema 17s.

-

Ditched proprietary motherboards for comparable BigTreeTech boards.

-

Ran Klipper firmware, with Fluidd/Tailscale cloud services.

After a few months of R&D, I successfully entered the world of custom FDM printers; and thus, Project Phoenix, was born.

1/4

1/4

WHY DID I START THIS IN THE FIRST PLACE?

Simply said: I'm a curious engineer. I wanted to see what could, or could not be, done with the equipment I had at my disposal.

And as it turns out, quite a lot could be done.

1/4

This project quickly cascaded into a race to the end of FDM's capabilities. In V1, I pushed the Anycubic chassis as far as it could go; I successfully hit speeds of up to 300mm/s.

However, this didn't last long. The toolhead wobbled, the Y axis shook at speed, and the firmware wasn't prepped for long prints.

I quickly realized that I needed a better chassis; and from there, the idea for V2 was born.

WHERE V1 WENT:

Full Gallery

of Project Phoenix: V1

bottom of page