Phoenix is a CoreXY style, Fused Deposition Modeling (FDM) 3D printer. Specifically, this is the second iteration in the Phoenix lineup. This is my flagship creation; capable of up to 6 material objects, with industrial precision and build volume. It's a fully open-source, production-ready FDM printer engineered for education, innovation, and accessibility. Built using real, standardized hardware; it's a modular platform that anyone can learn from, modify, and build upon. Phoenix has been designed not just to print, but to be modified, studied, and experimented with – it's purpose is to ignite motivation in others to continue this world forward.

WHAT IS PROJECT PHOENIX?

Key Features:

-

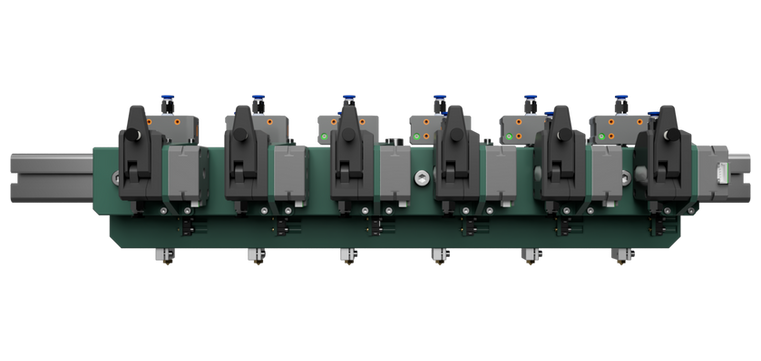

6 Color/Material printing via 6 individual toolheads

-

*Hot swaps toolheads during printing.

-

-

Large build volume: 400mm^3+

-

Expandable

-

-

Standardized hardware/equipment:

-

SBR/MGN rails

-

Euro-spec aluminum extrusions

-

BigTreeTech microcontrollers

-

Nema motors

-

-

Fully open-source:

-

Firmware: Klipper

-

Custom brackets: free to download, manufacture, and modify as desired. No catch.

-

-

High-speed printing:

-

Up to 600mm/s+ with Nema 23 motors

-

-

Overbuilt design:

-

Anyone is welcome to modify this machine, as the chassis has been purposely overbuilt to accommodate any forceable upgrades users may desire.

-

Project Phoenix is more than a machine — it’s a tool for transformation.

In Fall 2025, I’ll be presenting Phoenix at the Fremont STEM Academy, where it will serve as a real-world case study in engineering, fabrication, and open-source development.

Why Phoenix belongs in the classroom:

-

Students don’t just use Phoenix — they build it

-

Every bracket, board, and belt teaches real engineering concepts

-

Open systems = endless opportunities for modification and experimentation

-

Perfect for STEM clubs, makerspaces, and project-based learning environments

“We’re not just printing parts – we’re building engineers.”

Through Phoenix, students get hands-on experience with:

-

Mechanical design (frame rigidity, drive systems, tolerances)

-

Electronics & firmware (Klipper-based systems, stepper tuning, Raspberry PIs)

-

Problem-solving & iteration (design, test, improve – real-world R&D)

Built for Education – STEM

MORE THAN JUST A CAD MODEL.

MORE THAN JUST A CAD MODEL.

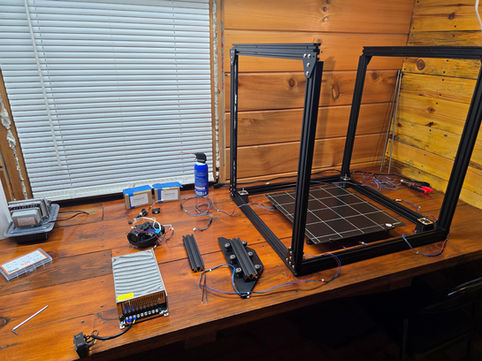

The manufacture of Phoenix V2 has already begun.

Full Gallery

of Project Phoenix: V2

.png)